Exploration activities like drilling and extraction are hazardous due to the release of toxic and flammable hydrocarbons, including volatile organic compounds (VOCs), polycyclic aromatic hydrocarbons, and particulate matter (PM2.5 and PM10). Key risk areas include drilling sites, extraction points, and storage facilities where gas accumulation is possible.

Equipping workers with effective gas detection equipment is crucial to alert them early to harmful gases, giving them time to take action and ensure safety.

Exploration

Exploration activities like drilling and extraction are hazardous due to the release of toxic and flammable hydrocarbons, including VOCs, polycyclic aromatic hydrocarbons, and particulate matter (PM2.5 and PM10). Equipping workers with gas detection equipment is essential to provide early warnings and allow timely action to ensure safety.

Perimeter Monitoring

Perimeter monitoring technology measures the concentration of specific chemicals at the boundaries of sites like petroleum refineries or chemical plants. It is essential for maintaining site-wide awareness and preventing the release or spread of harmful gases and materials.

Hot Works

Hot work activities carry significant risks, including ignition sources like flames, sparks, and high temperatures that can ignite flammable gases or materials. Using multi-gas portable monitors is essential for personal safety. Infrared technology for flammable gas detection is especially crucial, as it offers reliable performance in areas where traditional pellistor detectors may fail due to poisoning or high exposure levels.

Shutdown & maintenance

Localised leaks are a constant risk in the oil and gas industry, making high-quality fixed gas detection essential. Flammable gases may accumulate near pressure relief devices, requiring regular monitoring. Portable laser methane detectors can pinpoint leaks in hard-to-reach areas from a safe distance, reducing the need for personnel to enter hazardous environments during routine checks or investigations.

APPLICATIONS

-

Oil Refineries

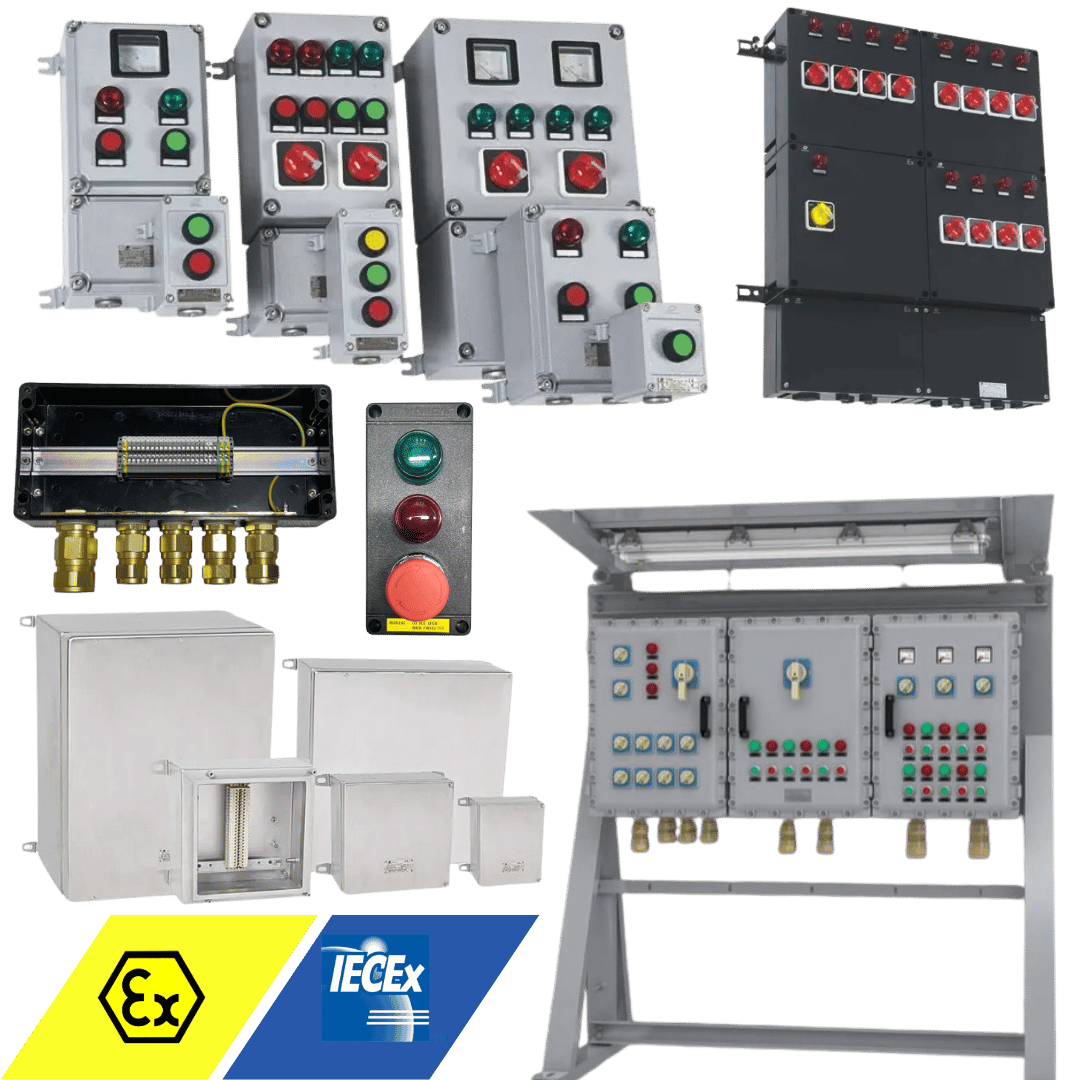

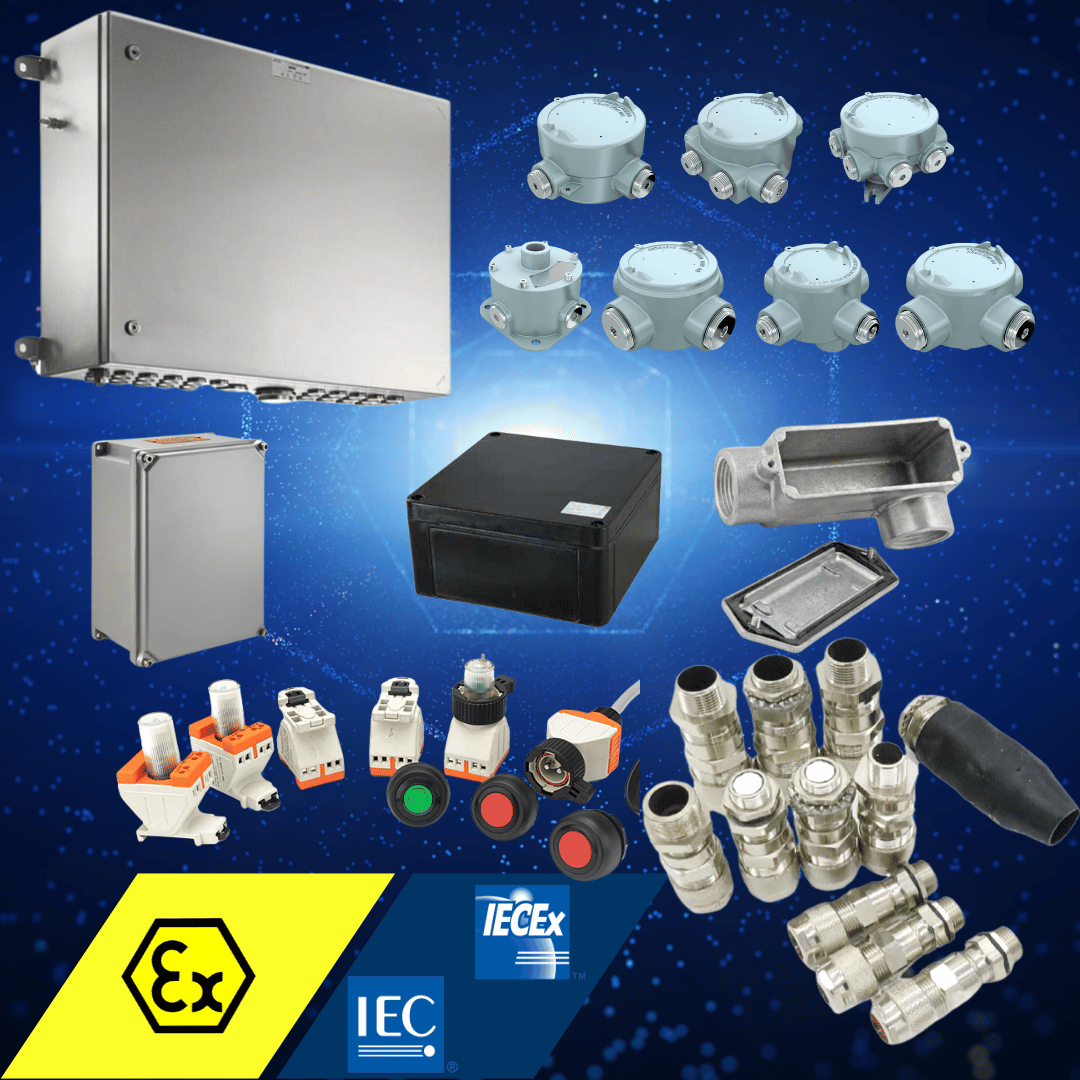

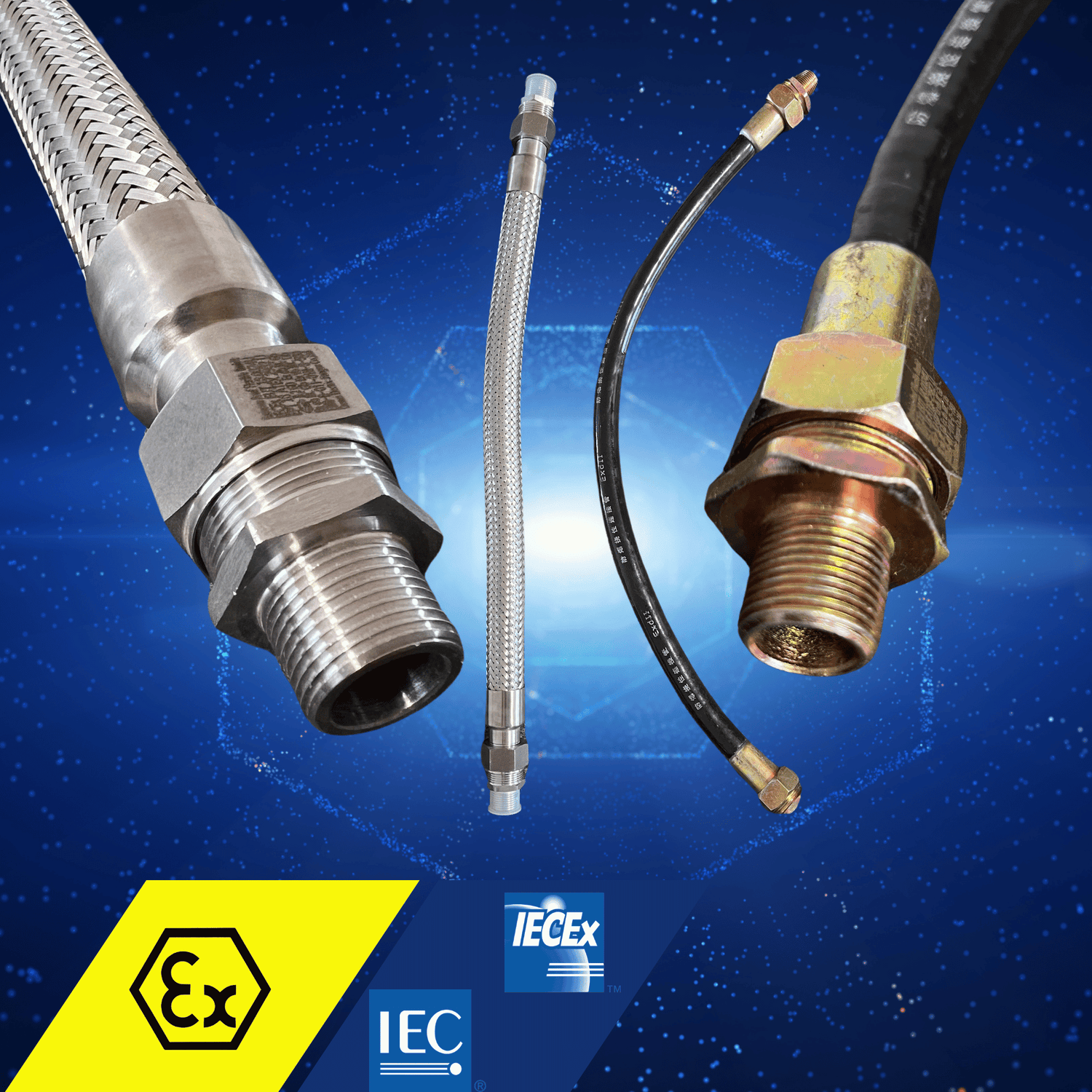

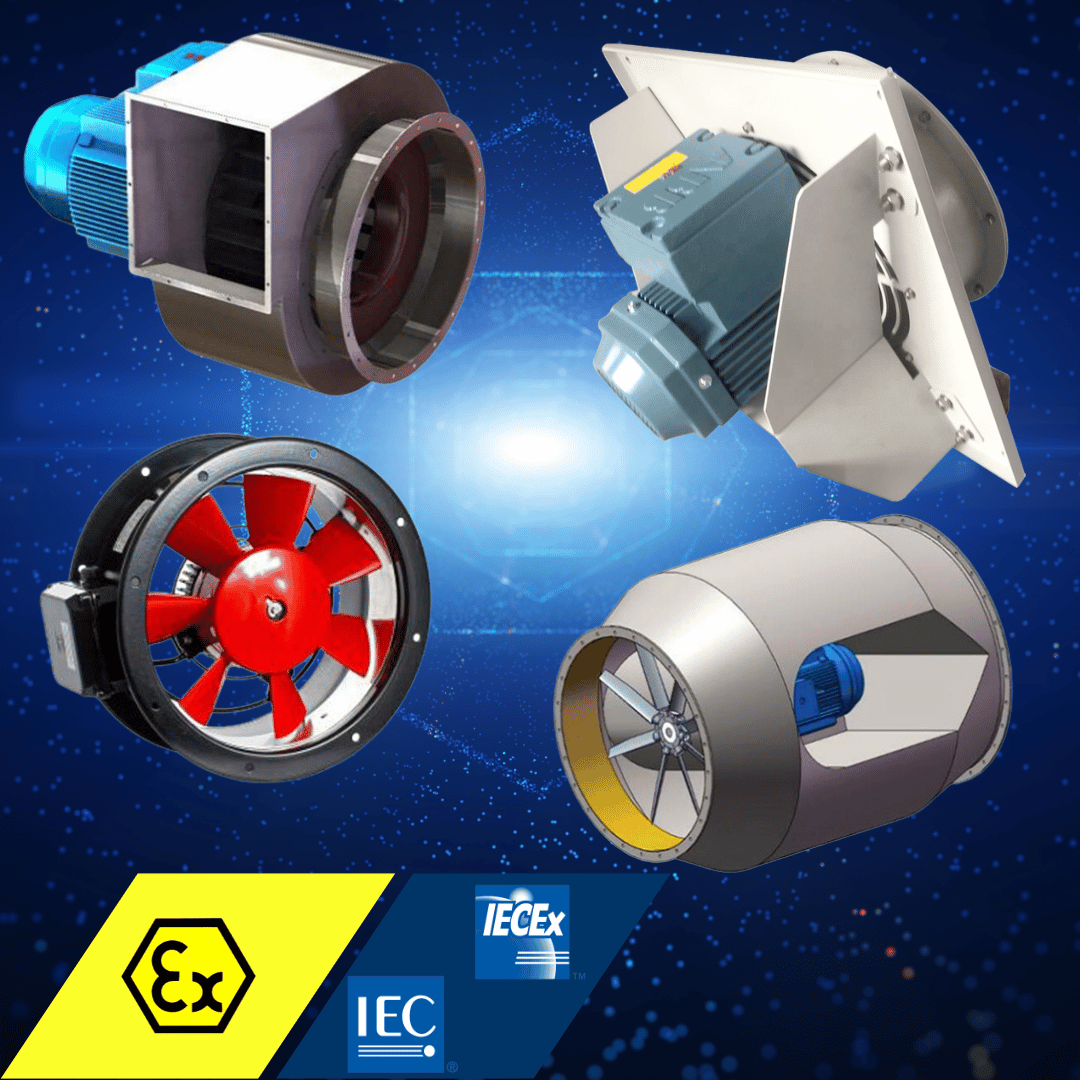

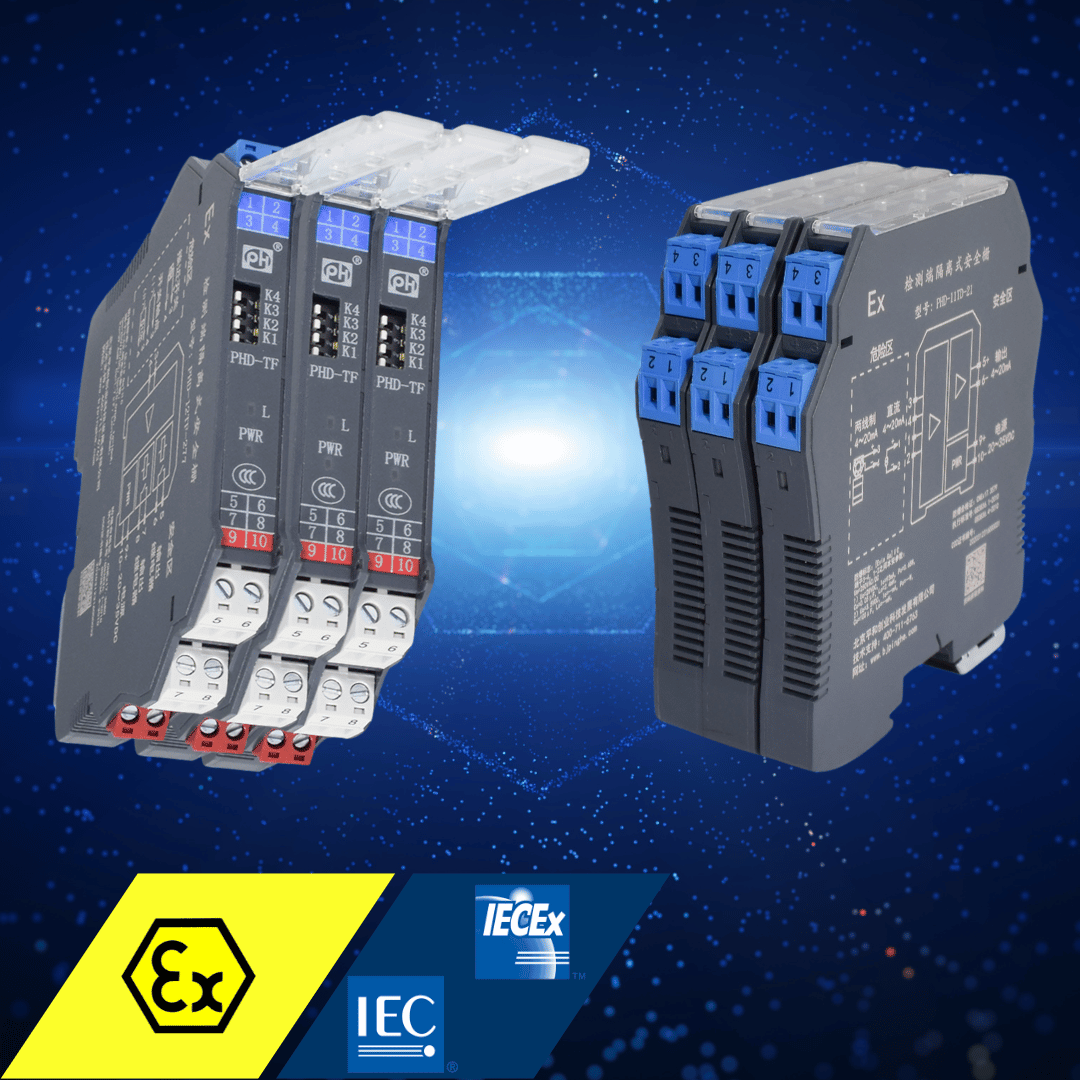

Hazardous Area Ex rated equipment ensures safe operations for flammable and toxic gases during refining processes.

-

Petrochemicals

Hazardous Area Ex rated equipment prevents hazardous chemical reactions and ensures safety in production plants.

-

Liquefied Natural Gas or Pipelines

Hazardous Area Ex rated equipment prevents leaks and explosions by monitoring pressurised pipelines.

-

Gas Storage

Continuous gas detection is critical to avoid leaks in large storage tanks, ensuring the safety of personnel and equipment.

-

Fuel Gas

Monitoring for combustible gases minimises fire risks in systems that use fuel gases for power generation.

-

Drilling

Gas detection systems ensure worker safety by detecting harmful gases released during drilling operations.

-

Exploration

Detecting the presence of gases in exploration sites aids in identifying resource deposits and prevents potential hazards.