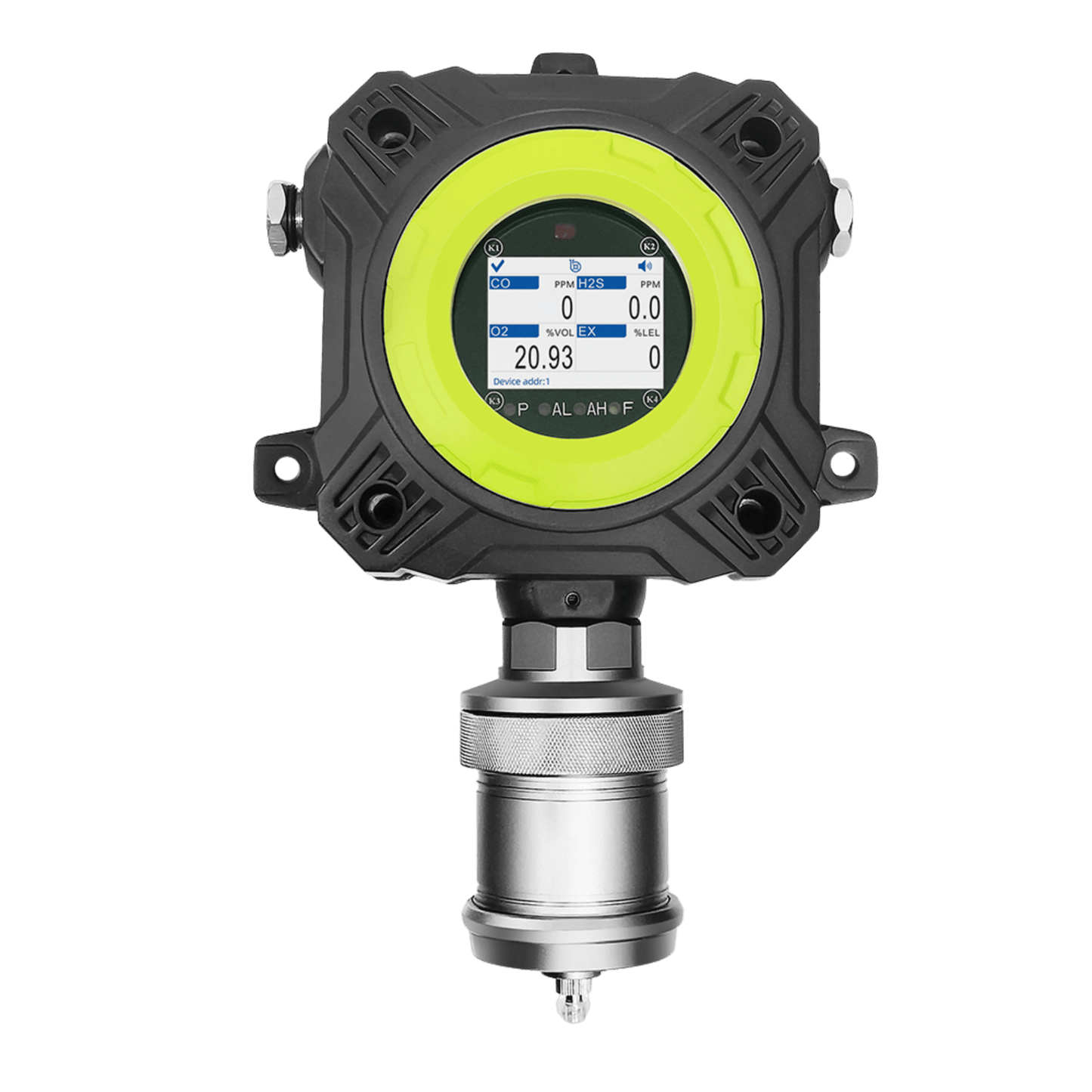

Ex Sampling Point Fixed Gas Detector Monitor - IECEx ATEX Hazardous Area Zone 1,2

Ex Sampling Point Fixed Gas Detector Monitor - IECEx ATEX Hazardous Area Zone 1,2

Couldn't load pickup availability

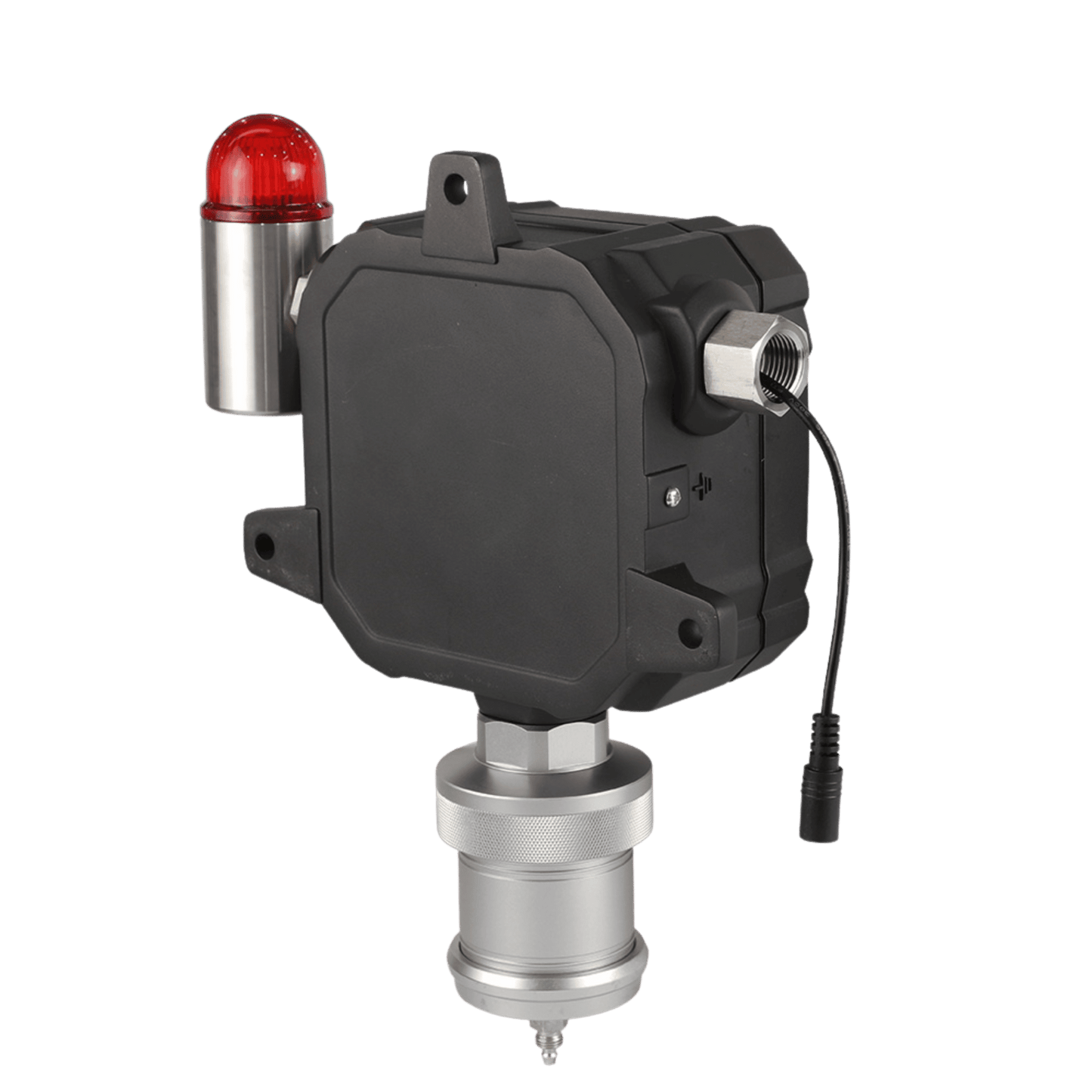

Sampling Point Fixed Gas Detector Monitor with built-in suction pump for sampling and up to 6 kinds of gases can be detected at the same time. This gas detector sets the stand in Ex rated explosion-proof gas detection. Engineered to endure and perform in the harsh challenges of the industrial environments with moisture, dirt, dust, corrosion, and vibration.

Harnessing equipment protection levels of Intrinsic Safety "ia", Flameproof "db". Suited for the most challenging hazardous atmospheric conditions found in industries such as oil and gas, marine, petrochemical, chemical, petroleum, manufacturing etc. Covered by the IECEx and ATEX certification, brings a compliant solution to hazardous areas.

Standard 4-20mA current signal, RS485 modbus signal, 1 set of relay signal output. making it compatible with most control systems. Additional magnetic wand design, it’s easier to navigate the control menu.

Collapsible content

Technical Datasheet

Shipping

We aim to process and get your delivery with you as quick as possible -

Shipping rates and delivery times are calculated at checkout.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

Calibration

To ensure you keep up to date with your metrology requirements, by adding the traceable standards calibration test report certificate.

FAQ

- Is there a maximum backpressure allowable on the vent lines? 90-110kpa

- Vent port size? M10*0.75mm

-

Hazardous Area Certified

Equipment Protection Level

IECEx

- Ex db IIC T6 Gb

-

FEATURES

Modular gas chamber for maintenance simply and conveniently

- Plug and play air chamber module replacement.

- Two-key magnetic bar design, no need to open the cover, to achieve on-site maintenance and operation of the detector in any explosion-proof area.

- 24h continuously monitoring, data will real-time display.

-

FEATURES

- Standard 4-20mA current signal, RS485 digital signal, 1 set of relay signal output

- Optional 2 groups of relay signals, voltage 1 ~ 5V, standard Hart

- Optional LORA, 4G and other wireless transmission.

- Can be installed with computer software, to transmit the data to computer, workers can remote monitor the data

- Die-cast aluminium case, IP66/67 protection degree, water-proof, dust-proof, explosion-proof.

Applications

-

Chemical & Petrochemical Plants

Location: Process rooms, tank farms, valve skids.

Use: Detect toxic or flammable gas leaks before they pose a threat to personnel or operations. -

Laboratories and Clean Rooms

Location: Fume hoods, storage cabinets, or isolated experiment chambers.

Use: Ensure containment of toxic gases or chemical vapors without disturbing the controlled environment. -

Wastewater Treatment Facilities

Location: Sludge digesters, underground pits, and sewer access points.

Use: Monitor for hydrogen sulfide (H₂S) or methane buildup from a central location without manual entry.

What Is a Sampling Pump Type Gas Detector?

A sampling pump gas detector is a gas detection device equipped with a built-in or external pump that actively draws air from a specific location—such as a confined space, duct, tank, or pipeline—into the sensor chamber for analysis.

Unlike diffusion-type gas detectors that rely on natural air movement, sampling pumps provide a proactive approach to gas detection, making them ideal for hard-to-reach or hazardous areas.

A fixed wall-mounted sampling pump gas detector is a permanently installed device designed to actively draw air from remote or enclosed areas into the detector using a pump. Unlike standard diffusion sensors that rely on ambient airflow, these units use forced air sampling through tubing—making them ideal for challenging environments or remote detection points.

These detectors are often installed in control rooms, outside confined spaces, or in designated hazardous zones where continuous monitoring is critical.

Add Calibration Service

Ensure to keep up to date with your metrology requirements, by adding the calibration test report certificate.

Why Use a Fixed Sampling Pump Gas Detector?

1. Remote Monitoring

Ideal for inaccessible or dangerous zones, allowing continuous monitoring without entering hazardous areas.

2. Improved Accuracy

Actively draws in air samples, reducing the chance of false readings due to stagnant air pockets.

3. Multiple Point Sampling

One detector can sample air from multiple locations using solenoid valves and switching manifolds.

4. Regulatory Compliance

Many industries require continuous monitoring in confined or enclosed spaces to meet safety regulations such as:

AS/NZS 60079

OSHA 29 CFR 1910.146

IECEx & ATEX standards for explosive atmospheres

-

Pre & Post After Sales Support

After Sales Support

We offer after sales support on all our products including

- Installation

- Configuration

- Maintenance

- Repair

- Calibration

-

Calibration & Repair

Calibration ServicesOur accredited laboratory is tailored to conduct traceable standard calibrations and repairs on all our equipment.

Contact form

-

Oil & Gas

Where CH₄ Gas Detectors Are Used:

- Monitors methane leaks during drilling and extraction.

- Detects gas releases in confined spaces and open-air operations.

- Ensures safe handling of extracted methane.

- Pipeline Compressor Stations: Monitors methane leaks in gas transmission lines.

- LNG & CNG Storage Facilities: Ensures safety in liquefied and compressed natural gas storage.

- Gas Pumping Stations: Prevents leaks in high-pressure gas transportation.

- Refinery Processing Units: Monitors methane emissions in cracking and distillation processes.

- Petrochemical Plants: Ensures safety in methane-based chemical production.

- Gas Distribution Networks: Detects leaks in natural gas delivery systems.

-

Chemical & Petrochemical Plants

Where CH₄ Gas Detectors Are Used:

- Steam Methane Reforming (SMR) Units – Converts methane into hydrogen and carbon monoxide for ammonia and methanol production.

- Ammonia Production Plants – Uses methane-derived hydrogen to synthesize ammonia (NH₃) for fertilizers.

- Methanol Plants – Converts methane into methanol for chemical and fuel production.

- Cracking & Reforming Units – Breaks down hydrocarbons to produce ethylene, propylene, and benzene.

- Gas Processing & Fractionation Plants – Separates methane, ethane, and other light hydrocarbons from raw gas streams.

- Polymer & Plastics Plants – Uses methane-derived chemicals to create polyethylene and polypropylene.

- Gas Storage Tanks – Monitors methane leaks from pressurized storage vessels.

- Pipeline Transfer Stations – Detects leaks in methane transport pipelines within the plant.

- Flare Gas Recovery Units – Monitors methane levels before gas is burned.

-

Wastewater Treatment Plants (WWTPs)

Where CH₄ Gas Detectors Are Used:

- Digester Tanks – Monitors methane leaks from gas-tight digestion chambers.

- Gas Storage Domes – Ensures methane does not accumulate in biogas holding tanks.

- Biogas Collection & Piping Systems – Detects leaks in transport lines to prevent fire hazards.

- Sludge Dewatering Units – Detects methane leaks in belt presses and centrifuges.

- Sludge Drying Beds & Thermal Treatment Units – Monitors gas emissions in drying and incineration processes.

- Sludge Storage Tanks – Ensures methane levels remain below explosive limits.

- Sewer Manholes & Underground Tunnels – Detects methane buildup in enclosed areas.

- Lift Stations & Pumping Stations – Prevents gas leaks from wastewater transport systems.

- Stormwater & Overflow Tanks – Monitors methane presence during high-load periods.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.