Collapsible content

Technical Datasheet

Shipping

Manufacturing lead time is dependant on quantity ordered. This is excluding the delivery lead time which is estimated at checkout.

We aim to process and get your delivery with you as quick as possible.

Please contact us to retrieve the estimate lead times for your order.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

-

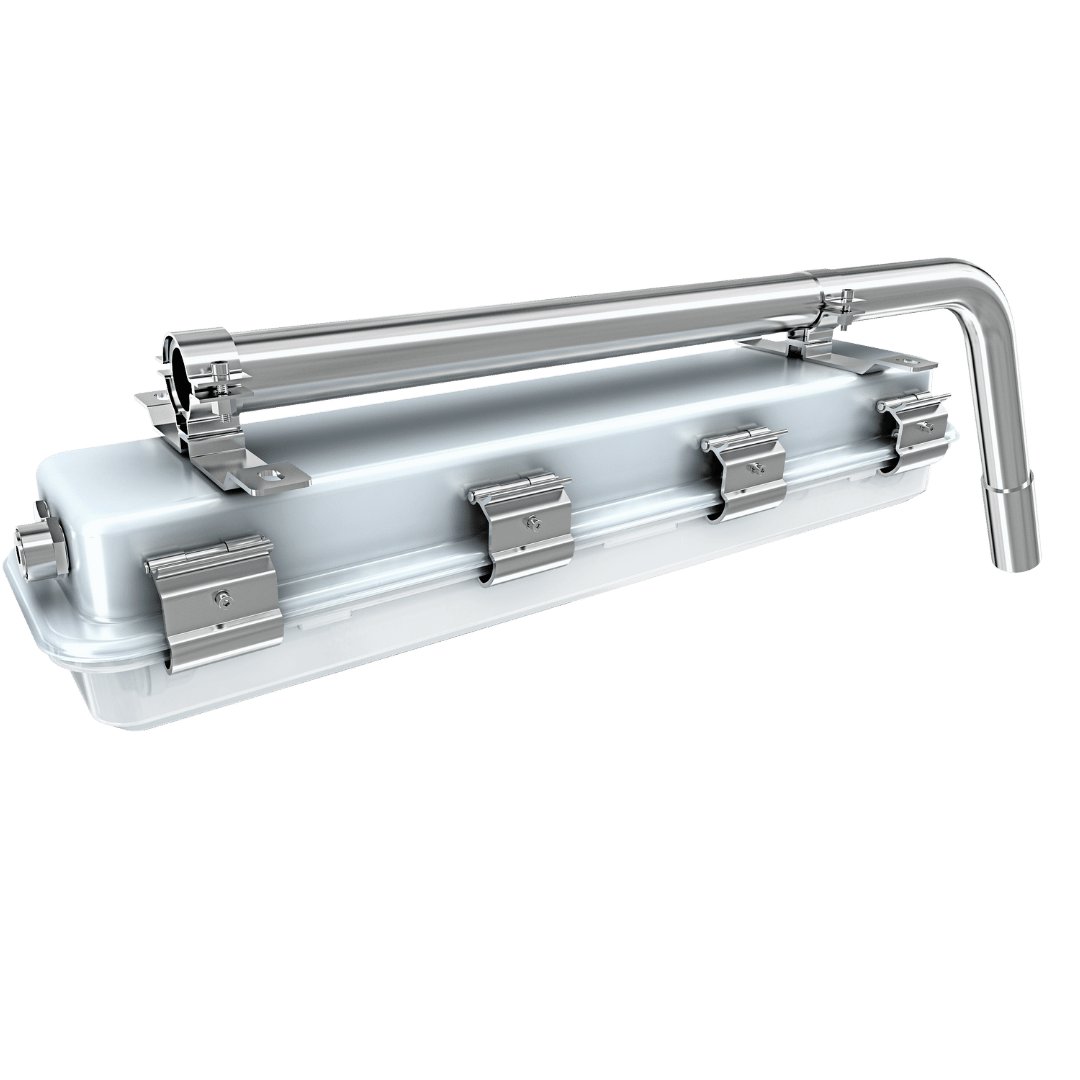

Hazardous Area Certified

Certification

- IECEx CSAE 24.0002X

Zone Location

IECEx

- Ex db eb mb IIC T6/T5 Gb

- Ex tb IIIC T80°C/T95°C Db IP66

ATEX

- Ex II 2GD - Ex db eb mb IIC T6/T5 Gb

- Ex II 2GD - Ex tb IIIC T80°C/T95°C Db IP66

-

Electrical Safety Certified

- IP66

- IK08/IK10

- 1200 hours Salt spray

- Ambient Rating: -40°C to 50°C

- Zones 1&2, Zone 21&22

-

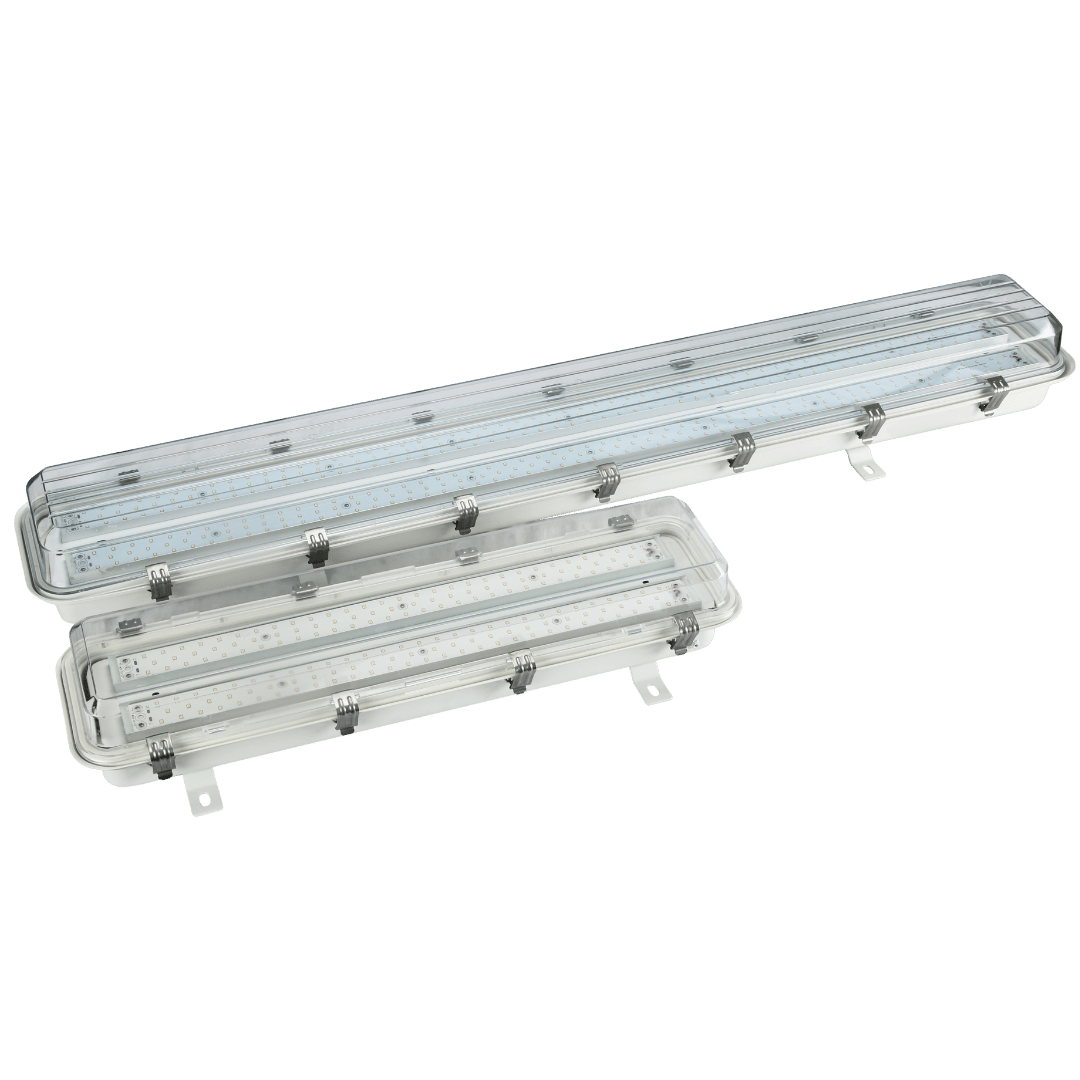

Construction

- UV Fiberglass Polycarbonate Lens

- Suitable for dead end, through feed* or single-ended “T” wiring

- Replaceable LED light strip

- Mounting for Ceiling, Walls, Hooks, Poles, Arms, Stanchions

- Emergency battery back-up (90 minutes + push to test)

Case Studies

-

Propane Transportation Facility

Propane transportation facility lighting design made by our lighting engineers. This install we used *3 40W Ex rated Zone 1 LED Jelly Jar lights, with mounted height of 4m. The propane transport area, measuring 2.4x12m achieved an average illumination of 12.9 foot-candles (fc).

-

Chemical Plant

Chemical plant lighting photometric design made by our lighting engineers. This install we used *4 150W Ex rated Zone 1 LED Jelly Jar lights, with mounted height of 4.5m. The sub level grading height was 3m, and achieved an average illumination of 70fc while the main level ceiling was 4.2m with an illumination average of 34.5 fc.

-

Paint Booth

Spray paint booth lighting photometric design made by our lighting engineers. This install we used *9 60W Ex rated Zone 1 LED Linear Lights, used on a 12x2.4m paint booth with 2.7m ceilings. The fixtures were mounted on the wall and provided a maximum of 290 foot candles with a uniformity of 1.22-3.96.

Lighting Design

-

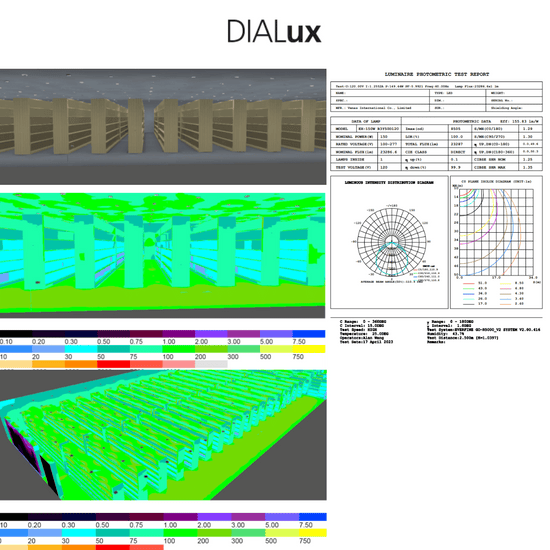

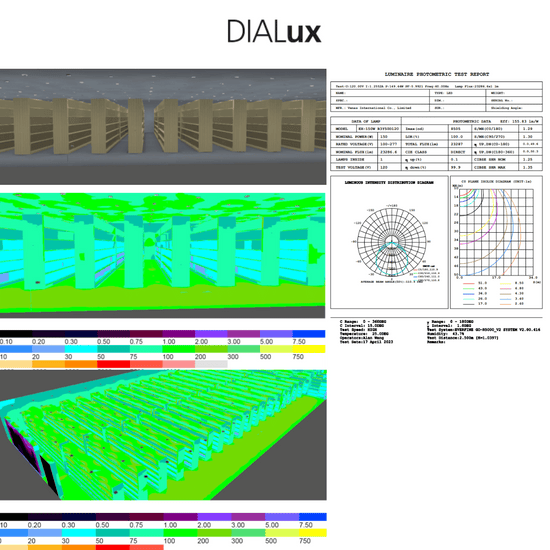

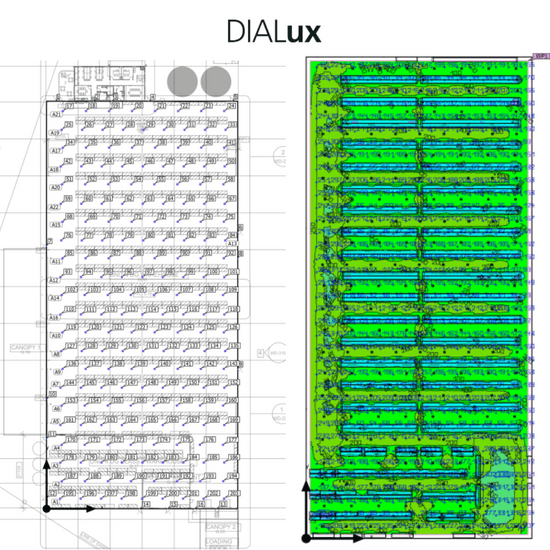

Illumination Mapping

2D and 3D mapping helps better placement of lighting, as a result of the colour view from the pseudo view of coverage. Resulting in cost effective solution to knowing exactly where and how many lights are needed.

-

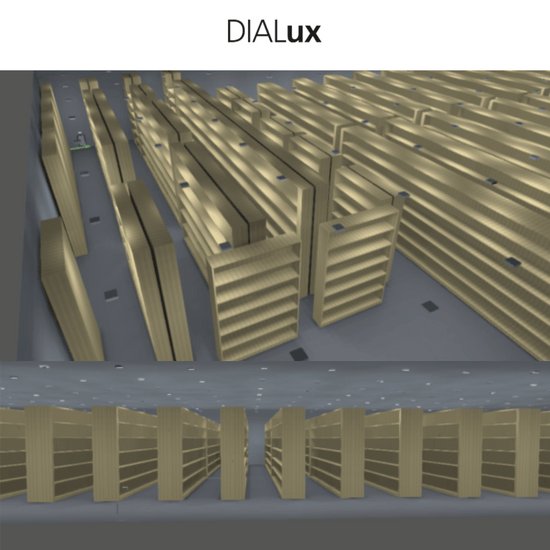

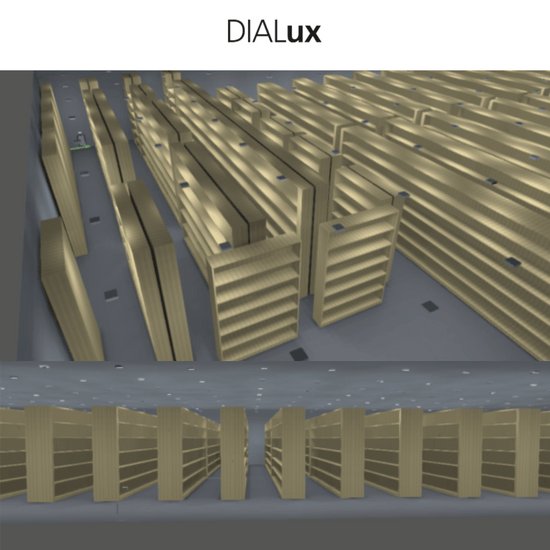

3D Site Modelling

A professional addition to provide a detailed layout of the near real life site that includes all the construction variable on site. Visually seeing how object are effecting blind spots.

-

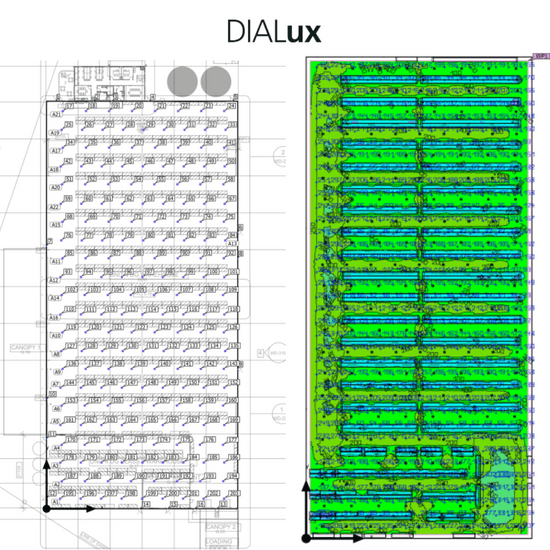

2D Light Positioning

Using your site drawing plans, we can plot the lights and draw a coverage area via the spread of lux levels, from the lights.

Introduction to Apexio Industrial

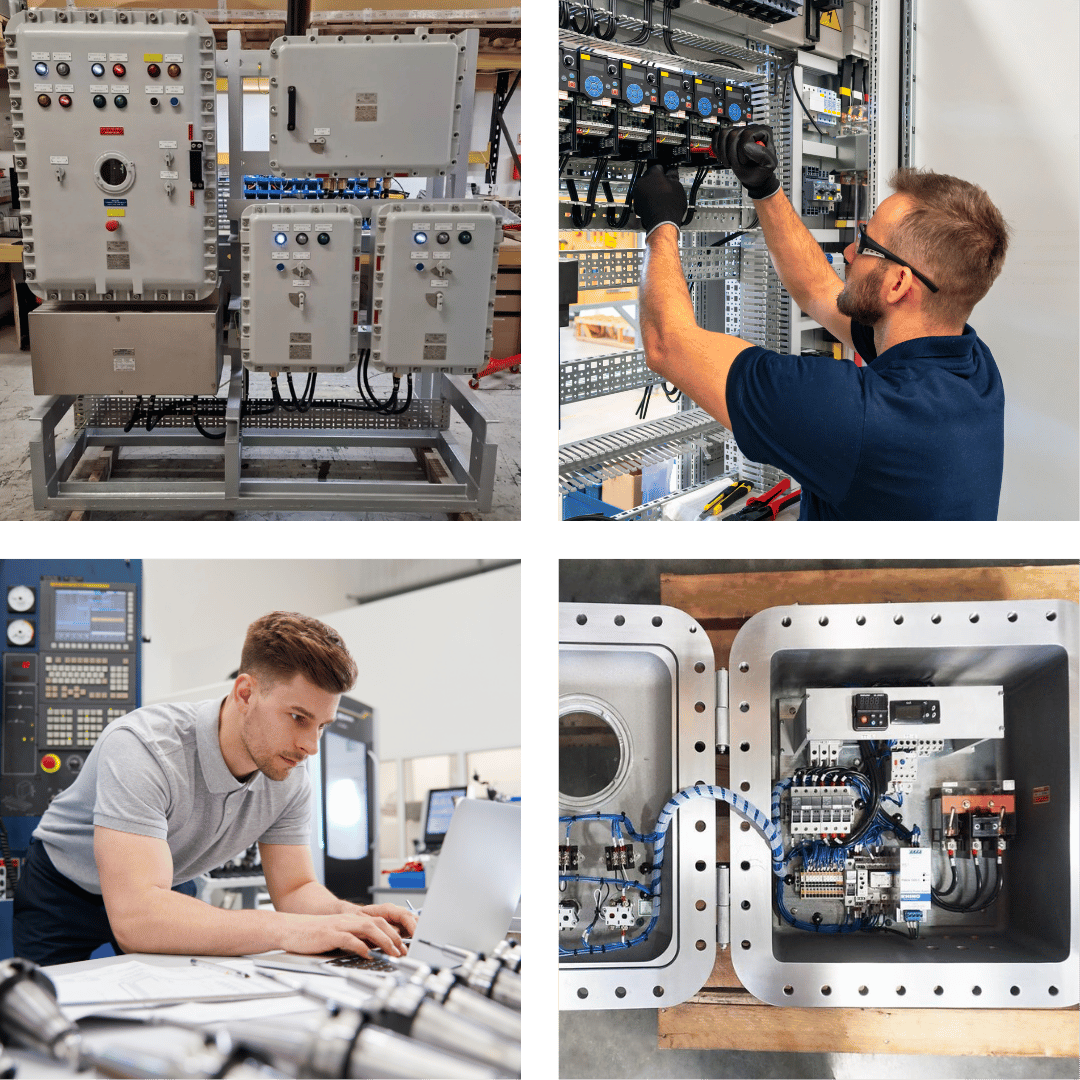

Need expert help with custom electrical design, fabrication & install?

-

Design & Selection

Leverage our expert resources and state-of-the-art IECEx / ATEX certified workshop to turn your hazardous area electrical design into reality. With unparalleled knowledge and precision, we ensure your project meets the highest safety and compliance standards while delivering exceptional results.

-

Manufacturing & Fabrication

Discover our comprehensive range of IECEx / ATEX certified solutions, from pre-approved designs to fully customized control stations, motor starters, and distribution panels. Whether your project requires standard options or tailored systems, we deliver reliable, compliant, and high-performance solutions for hazardous environments.

-

Test & Commission

We offer comprehensive turnkey solutions, providing end-to-end services to install, commission, and maintain your systems with precision and expertise. Trust us to deliver seamless integration and ongoing support for reliable performance in any environment.

Speak to our technical sales team today.

Pre & Post Sales Support

- We offer technical after sales support to ensure our clients are backed by our team.

- Whether you need support with custom project fabrication, calibration, on-site installation.

- We are here to bring a partnered business relationship with you.

- Our fulfilment warehouse has stocking capabilities for small or large projects.

Contact form

Australian Operated and Owned.

OUR CORE VALUES

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.